Installing an elevator in your villa transforms accessibility and property value, but the hoistway frame—the structural backbone—demands careful consideration. Unlike commercial systems, residential elevator frame hoistways require precision engineering for space efficiency, noise reduction, and seamless home integration. This guide explores critical technical aspects you won't find in generic brochures.

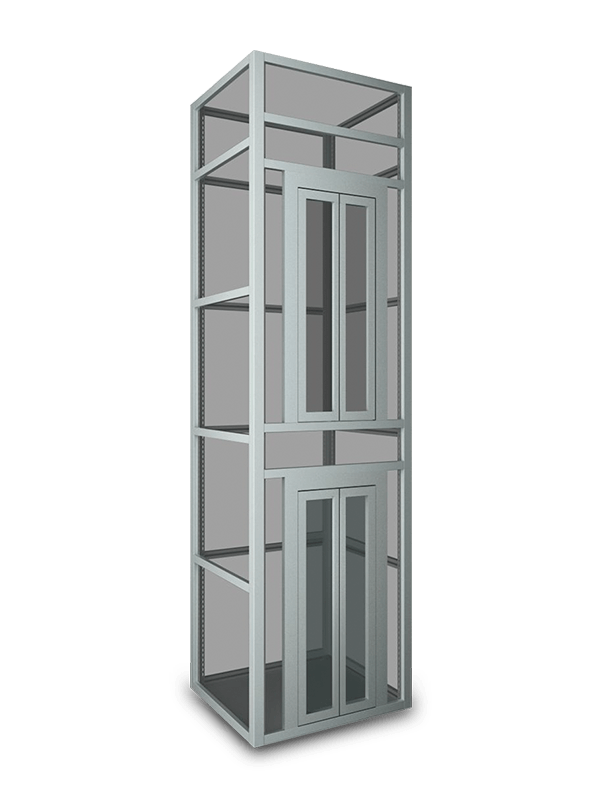

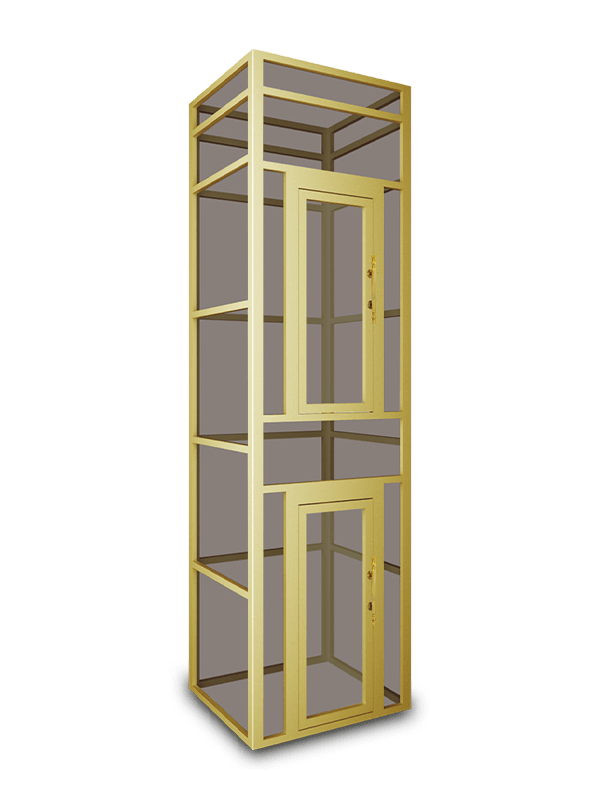

What is a Frame Hoistway?

A frame hoistway is the self-supporting elevator structure housing the cab, rails, and mechanical components. In villas, it's typically constructed from steel or aluminum frames with integrated panels, eliminating the need for traditional masonry shafts. This modular hoistway system enables faster installation and flexible placement within existing home layouts.

Core Components Explained

Vertical Uprights: Load-bearing columns anchoring rail supports.

Cross Beams: Horizontal members providing lateral stability.

Wall Panels: Pre-finished sections (steel, glass, or composite) enclosing the shaft.

Rail Brackets: Precision-mounting points for elevator guide rails.

Benefits of Frame Hoistways for Villas

Space Optimization: Compact elevator frames need only 100mm clearance from walls, maximizing room space. Ideal for narrow hoistway residential retrofits.

Reduced Construction Impact: No masonry work means minimal dust and structural modifications. Installation often completes in 3-5 days versus weeks for built shafts.

Design Flexibility: Customizable finishes (wood-grain, metallic, or frameless glass) match your interior. Enables curved villa elevator designs impossible with concrete.

Future-Proof Maintenance: Removable panels grant full component access without destructive demolition.

Material Selection: Beyond Basic Steel

Frame materials dramatically impact performance. Here's a technical comparison:

| Material | Structural Rigidity | Noise Dampening | Corrosion Resistance | Weight Impact | Best Applications |

| Galvanized Steel | Excellent (High load capacity) | Moderate (Requires acoustic panels) | Good (Zinc coating protects) | Heavy (Needs reinforced floors) | Tall shafts (3+ floors), heavy cabs |

| Aluminum Alloy | Good (With strategic bracing) | Superior (Inherent vibration absorption) | Excellent (No rust) | Light (Suitable for timber floors) | Retrofits, coastal homes, weight-sensitive installs |

| Hybrid Composite | Variable (Fiberglass-reinforced options) | Exceptional (Low resonance transmission) | Outstanding (Humidity/chemical resistant) | Ultra-Light (Eases structural constraints) | Historic homes, moisture-prone areas |

Critical Installation Considerations

Floor Load Analysis: Steel frames add 180-250kg/m². Always verify floor joist capacity with a structural engineer. Lightweight hoistway solutions may be essential for upper floors.

Plumb Tolerance: Frames must be vertically aligned within ≤5mm deviation over 10m height. Misalignment causes uneven rail wear and increased noise.

Fire Rating Compliance: Ensure panels meet local fire containment regulations (typically 30-60 minutes). Fire-rated hoistway panels use mineral cores or intumescent seals.

Utility Chases: Integrate conduit pathways within frames for cab wiring, lighting, and emergency comms to avoid surface-mount conduits.

Noise Control Strategies

Frame hoistways can transmit vibrations if improperly engineered. Mitigate with:

Decoupling Systems: Rubber isolators between frame and building structure prevent vibration transfer.

Acoustic Panels: Panels with 25dB+ STC ratings containing mass-loaded vinyl or foam cores.

Rail Dampers: Polymer sleeves on rail brackets absorb high-frequency harmonics.

Sealed Joints: Butyl tape or silicone seals at panel junctions block airborne noise leakage.

Maintenance & Longevity

Frame hoistways require less maintenance than masonry but still need attention:

Annual Checklist:

- Inspect fasteners for torque integrity

- Verify fire seals remain uncompromised

- Check for corrosion at cut edges (even galvanized steel)

- Test emergency lighting wiring within frames

Lifespan Expectancy: Properly maintained frames last 25-30 years. Aluminum/composites resist corrosion better in humid climates.

Future-Proofing Your Installation

Adaptability: Specify frames compatible with both traction and hydraulic drives for future upgrades.

Expansion Previsions: Leave space for additional guide rail brackets if heavier cabs might be installed later.

Smart Integration: Install conduit for IoT sensors monitoring frame stress, alignment, and vibration.

Conclusion

A villa elevator frame hoistway is more than just metal—it's a precision-engineered ecosystem demanding material expertise, acoustic planning, and foresight. By prioritizing low-noise residential frames and corrosion-resistant materials during design, you ensure decades of smooth, quiet operation. Always engage specialists experienced in custom villa hoistway solutions rather than generic elevator contractors. The right frame transforms your elevator from functional machinery to an invisible, integral part of your home.

English

English عربى

عربى Deutsch

Deutsch Español

Español Français

Français русский

русский 日本語

日本語 简体中文

简体中文