Introduction to Home Elevators

Household elevator provide accessibility, convenience, and can significantly increase property value. Unlike commercial elevators, residential models are designed for lower usage frequency, limited space, and architectural integration. Modern home elevators are quiet, energy-efficient, and require minimal structural modifications.

When selecting a home elevator, homeowners must consider multiple factors: available space, number of floors served, weight capacity, budget, installation requirements, and maintenance needs. This guide examines the five primary types of residential elevators, their mechanisms, advantages, limitations, and ideal applications.

Comparison of Home Elevator Types

| Type | Mechanism | Space Needed | Installation Time | Max Floors | Cost Range |

| Hydraulic Elevator | Fluid pressure piston | Requires machine room | 2-4 weeks | 6 floors | $30,000-$50,000 |

| Traction Elevator | Cable and counterweight | Machine room optional | 3-5 weeks | 8 floors | $35,000-$60,000 |

| Pneumatic Vacuum | Air pressure differential | Minimal clearance | 1-2 weeks | 3 floors | $45,000-$75,000 |

| Screw Driven | Rotating screw mechanism | No machine room | 2-3 weeks | 5 floors | $25,000-$40,000 |

| Chain Driven | Electric chain motor | Minimal shaft space | 1-3 weeks | 4 floors | $20,000-$35,000 |

Hydraulic Elevators

Hydraulic elevators operate using a fluid-driven piston located below the elevator car. An electric pump pushes hydraulic fluid into the cylinder, raising the elevator. To descend, valves release fluid back into the reservoir.

Advantages

- Smooth, quiet operation

- Proven reliability with long service history

- Can handle heavier loads (up to 1,400 lbs)

- Precise leveling at floors

- Requires less overhead space than traction systems

Limitations

- Requires a separate machine room

- Hydraulic fluid maintenance needed

- Slightly higher energy consumption

- Slower speeds (typically 20-40 fpm)

- Potential for fluid leaks

Ideal for: Homes requiring high weight capacity, existing structures where overhead clearance is limited, and installations up to 6 stories.

Traction Elevators

Traction elevators use steel ropes or belts attached to the elevator car, looped over a drive sheave to a counterweight. An electric motor turns the sheave to move the elevator. Gearless versions offer superior performance but higher cost.

Advantages

- Energy efficient operation

- Faster speeds (up to 200 fpm)

- Smooth, comfortable ride quality

- No hydraulic fluid required

- Longer lifespan with proper maintenance

Limitations

- Requires significant overhead space

- More complex installation

- Higher initial cost than hydraulic

- Counterweight requires additional shaft space

- Regular rope/belt tension maintenance

Ideal for: New construction, taller homes (4+ stories), environmentally conscious homeowners, and situations where overhead space is available.

Pneumatic Vacuum Elevators

Pneumatic elevators operate using air pressure differentials. The cylindrical car moves within a transparent tube. To ascend, a vacuum pump removes air from above the car, allowing atmospheric pressure below to push it upward. To descend, valves allow air back into the top section.

Advantages

- Minimal structural modifications required

- No machine room or pit needed

- Self-supporting design

- Modern, distinctive appearance

- Energy efficient operation

Limitations

- Limited to 3 floors maximum

- Lower weight capacity (typically 500 lbs)

- Higher initial cost

- Smaller car dimensions

- Audible pump operation

Ideal for: Contemporary homes, retrofit installations, accessibility solutions, and situations where a distinctive design element is desired.

Screw Driven Elevators

Screw driven elevators use a large threaded steel column that runs vertically through the elevator car. An electric motor rotates a nut mechanism that travels along these threads, raising or lowering the car without cables or hydraulics.

Advantages

- Simplest mechanical design

- No hydraulic fluid or cables

- Compact installation footprint

- Minimal maintenance requirements

- Lower installation cost

Limitations

- Slower speeds (typically 20-30 fpm)

- Limited to 5 floors maximum

- Audible mechanical operation

- Lower weight capacity

- Not suitable for high-traffic use

Ideal for: Low-rise homes (2-3 floors), budget-conscious installations, and situations where minimal maintenance is preferred.

Chain Driven Elevators

Chain driven elevators use an electric motor to turn a sprocket that moves a heavy-duty chain. The chain is attached to the top of the elevator car and provides the lifting force. Guide rails keep the car aligned during movement.

Advantages

- Most affordable installation cost

- Minimal shaft space requirements

- Simple mechanical system

- Reliable operation

- Easy maintenance

Limitations

- Audible chain operation

- Limited to 4 floors maximum

- Lower weight capacity

- Vibration during operation

- Requires regular lubrication

Ideal for: Budget installations, short-distance vertical transportation (8-12 feet), and low-frequency usage scenarios.

Key Selection Factors

Choosing the right elevator involves balancing multiple considerations beyond just the mechanical type. These factors will help determine the most appropriate solution for your specific situation.

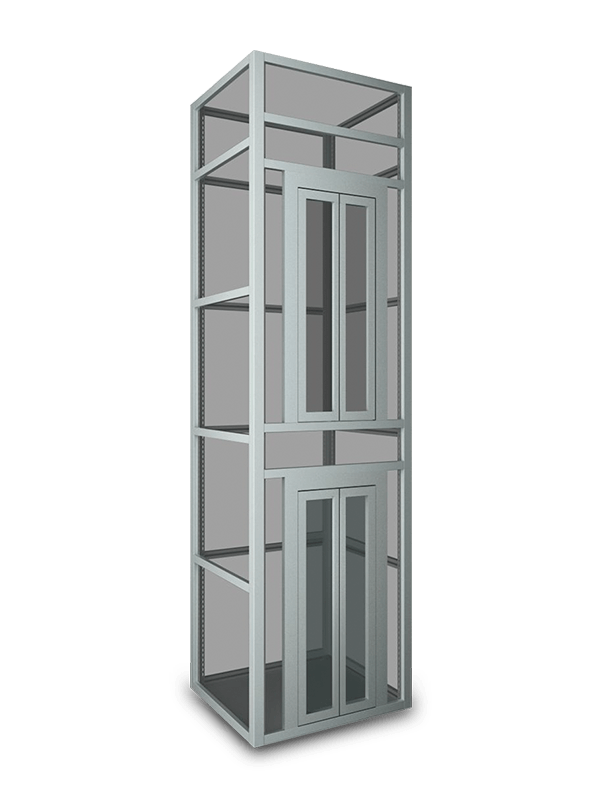

Space Requirements

Evaluate available space for the elevator shaft, machine room, and access points. Some designs require more space than others.

Installation Complexity

Consider structural modifications, construction timeline, and disruption to your household during installation.

Budget Considerations

Account for initial costs, long-term maintenance, energy consumption, and potential home value increase.

Safety Features

Prioritize emergency systems, backup power, door sensors, and compliance with safety standards.

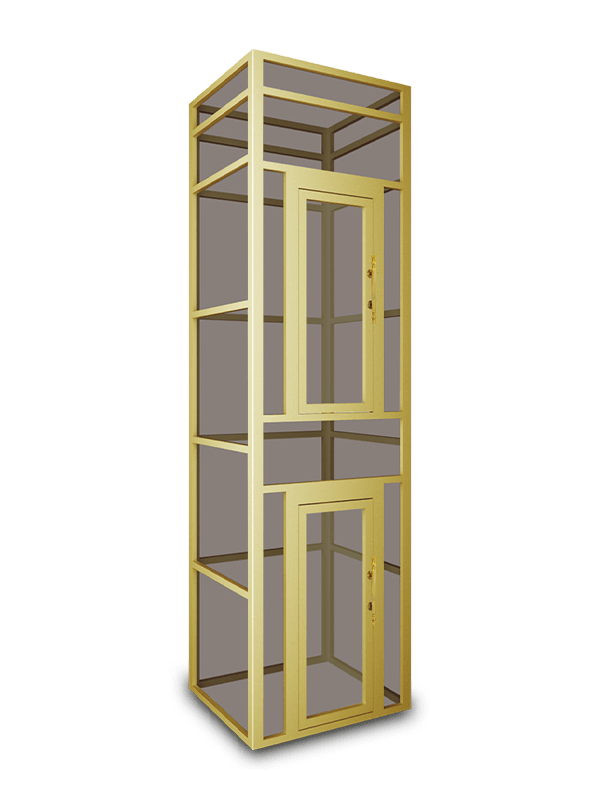

Aesthetic Preferences

Determine how the elevator will integrate with your home's architectural style and interior design.

Maintenance Needs

Understand the ongoing service requirements, inspection schedules, and potential repair costs.

Making Your Final Decision

Selecting the ideal home elevator requires careful evaluation of your specific needs, home structure, budget, and long-term expectations. Consider these final recommendations:

For new construction: Traction elevators offer the best combination of efficiency, performance, and quiet operation. The installation can be seamlessly integrated into the building design.

For retrofitting existing homes: Pneumatic vacuum or chain-driven models typically require the least structural modifications, making them ideal for renovations.

For budget-conscious homeowners: Screw-driven or chain-driven elevators provide reliable service at the lowest initial cost while still meeting basic accessibility needs.

For luxury installations: Custom hydraulic or high-end traction elevators with premium finishes offer the smoothest operation and most elegant appearance.

Before making a final decision, obtain multiple professional assessments, review maintenance requirements carefully, and consider how the elevator will serve your needs over the next 15-20 years. The ideal home elevator balances performance, aesthetics, reliability, and value to provide years of safe, convenient service.

English

English عربى

عربى Deutsch

Deutsch Español

Español Français

Français русский

русский 日本語

日本語 简体中文

简体中文