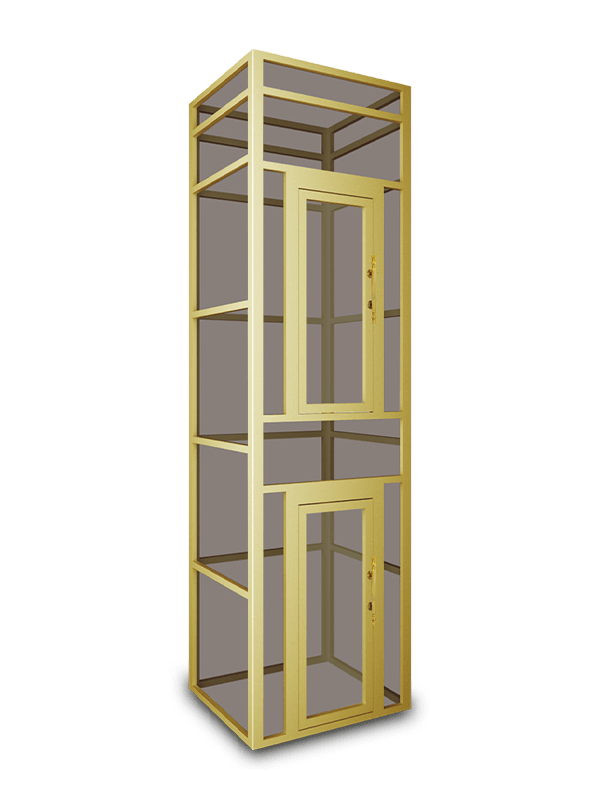

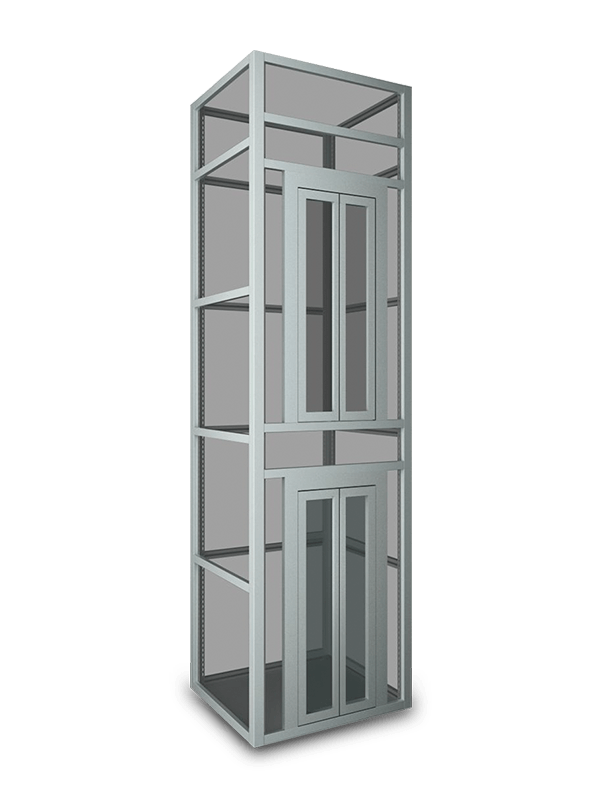

When designing or renovating a building, few elements blend the critical demands of engineering, aesthetics, and user experience quite like the elevator. It’s a space of transition, a small room that moves, and its interior design speaks volumes about the entire property. At the heart of this design are the elevator interior wall panel. They are more than just a surface; they are a statement of quality, safety, and style.

Choosing the right panels is a nuanced decision that balances durability, maintenance, budget, and design vision. This guide will walk you through everything you need to know to make an informed choice that will stand the test of time and traffic.

Why Your Choice of Elevator Wall Panels Matters

Elevators are high-traffic environments. They endure constant use, from the gentle touch of a hotel guest to the heavy impact of moving equipment in a service lift. The interior panels are the first line of defense against this daily wear and tear. Beyond durability, they define the atmosphere of the space. A sleek, stainless-steel finish conveys a modern, corporate efficiency, while rich wood veneers suggest warmth and traditional luxury.

Furthermore, the right materials contribute to safety (through fire ratings and slip resistance), ease of cleaning (a crucial consideration for public health), and even the acoustic properties of the cab, dampening noise for a smoother, quieter ride.

Key Considerations Before You Choose

Before diving into specific materials, establish your project’s core parameters:

Traffic Level & Usage: Is this a low-traffic residential elevator, a busy commercial office building, a hospital, or a industrial facility? The answer will dictate the required durability.

Budget: Costs can vary dramatically between materials and fabrication techniques. Establish a realistic budget per cab, including both material and installation costs.

Maintenance: What level of daily and periodic cleaning are you prepared for? Some materials require special cleaners and frequent polishing, while others need just a simple wipe-down.

Aesthetic Goals: What is the overall design theme of the building? The elevator interior should be a seamless extension of its architecture and interior design.

Codes and Regulations: Ensure the materials you choose comply with local building codes, particularly regarding fire safety (flame spread and smoke density ratings) and accessibility requirements.

A Deep Dive into Elevator Interior Panel Materials

Now, let’s explore the most common and effective materials used for elevator cab interior design, highlighting the pros, cons, and best uses of each.

1. Stainless Steel

A perennial favorite for its modern look and renowned strength, stainless steel is a top contender for durable elevator wall solutions.

Pros:

Extreme Durability: Highly resistant to dents, scratches, and corrosion, especially when using higher-grade (e.g., 304) or brushed finishes that hide minor imperfections.

Modern Aesthetic: Offers a clean, sleek, and professional look that works well in corporate, hospital, and modern residential settings.

Hygienic & Easy to Clean: Its non-porous surface can be easily sanitized with standard cleaners, making it ideal for healthcare facilities.

Fire Resistant: Naturally non-combustible.

Cons:

Shows Smudges: Particularly polished finishes can show fingerprints and water spots easily, requiring frequent cleaning.

Can Feel “Cold”: The aesthetic, while sleek, may not be suitable for projects aiming for a warm or traditional ambiance.

Cost: Higher-quality stainless steel can be a significant investment.

Best for: High-traffic commercial buildings, hospitals, airports, modern luxury homes, and industrial applications. A brushed stainless steel elevator finish is often the most practical choice.

2. Laminated Panels (PLP - Plastic Laminate Panels)

Laminates are one of the most versatile and cost-effective options for custom elevator interior panels. They consist of a decorative paper layer fused to a core substrate (like MDF or particleboard) under high heat and pressure.

Pros:

Unmatched Design Variety: Available in thousands of colors, patterns, and textures, including realistic wood grains, stone looks, and solid colors. This makes them perfect for custom elevator interior design.

Cost-Effective: Generally one of the most budget-friendly options.

Durable Surface: Resistant to stains, scratches, and moisture with proper sealing at the edges.

Easy Maintenance: Simple to clean with common, non-abrasive household cleaners.

Cons:

Vulnerable Edges: If the sealing at the edges is compromised, moisture can seep in and cause the substrate to swell.

Impact Damage: While scratch-resistant, they can be chipped or cracked by a sharp, high-impact blow.

Less Premium Feel: While high-pressure laminates (HPL) are excellent, they may not convey the same inherent luxury as natural materials.

Best for: Mid-range commercial projects, hotels, residential buildings, and any project requiring a specific color match or bold pattern.

3. Solid Surface Materials

Solid surface materials are acrylic or polyester-based composites that offer a seamless, non-porous finish. They are a premium choice for creating a modern elevator wall cladding with a high-end feel.

Pros:

Seamless Appearance: Panels can be thermally fused together, creating a virtually invisible joint for a beautiful, continuous look.

Repairable: Minor scratches and scuffs can be sanded out, restoring the surface to like-new condition.

Non-Porous & Hygienic: Resists mold and mildew and is incredibly easy to clean and disinfect.

Design Flexibility: Can be molded into curved shapes for a streamlined, organic design.

Cons:

Higher Cost: Among the more expensive material options.

Can Be Scratched: Softer than some materials and can be vulnerable to deep scratches from sharp objects.

Weight: Can be heavy, which may be a consideration for some elevator systems.

Best for: Hospitals, labs, high-end residential elevators, and luxury hotels where a seamless, hygienic, and elegant appearance is paramount.

4. Wood Veneers and Solid Wood

For timeless elegance and warmth, nothing quite compares to real wood. Options range from thin wood veneers over a substrate to solid wood panels.

Pros:

Classic Beauty & Warmth: Offers a traditional, luxurious, and inviting aesthetic that is difficult to replicate.

Natural Variety: Each grain pattern is unique, adding character and depth.

Durable Longevity: With proper finishing and care, wood can last for decades.

Cons:

Maintenance: Requires specific cleaning products and periodic refinishing or re-varnishing to protect against moisture and wear.

Vulnerability: Can be dented, scratched, and is susceptible to damage from moisture and humidity fluctuations.

Cost: High-quality wood, especially solid wood or exotic veneers, is a premium investment.

Best for: Luxury residential elevators, high-end hotels, corporate boardroom lifts, and traditional or classic architectural styles.

5. Glass and Mirror

Glass panels, whether clear, frosted, back-painted, or mirrored, are a powerful design tool for elevator interior modernization.

Pros:

Spaciousness: Mirrors are famously used to make small spaces feel larger and brighter.

Modern Aesthetic: Clean lines and a sleek look define contemporary design.

Light Reflection: Helps distribute light evenly throughout the cab, improving visibility.

Durability: When tempered or laminated, safety glass is highly impact-resistant and safe.

Cons:

Maintenance: Shows fingerprints, smudges, and water spots very easily, requiring constant cleaning.

Cost: Custom-cut, tempered, and finished glass can be expensive.

Potential for Damage: While strong, a sharp impact can shatter tempered glass, requiring full replacement.

Best for: Creating a sense of space in smaller cabs, modern design schemes, and decorative accent panels paired with other materials.

6. PVC & FRP (Fiberglass Reinforced Plastic)

These are often considered as practical, cost-effective elevator interior solutions for projects where budget is a primary driver.

Pros:

Low Cost: Typically the most affordable option.

Lightweight: Easy to handle and install.

Moisture Resistant: Impervious to water damage, making them suitable for outdoor or humid environments.

Cons:

Less Premium Appearance: Can often look and feel cheap or plastic-like.

Durability Concerns: More prone to scratching, cracking, and fading over time compared to other materials.

Limited Design Options: Fewer aesthetic choices available.

Best for: Budget-conscious projects, industrial elevators, freight elevators where appearance is secondary, and moisture-prone environments.

The Selection Guide: Matching Material to Application

To put it all together, here is a quick guide to steer your decision:

Corporate Office Building: Prioritize durability and a professional aesthetic. Brushed stainless steel, high-quality laminates, or solid surface materials are excellent choices.

Luxury Hotel/Residential: Focus on elegance and warmth. Wood veneers, luxury elevator wall materials like back-painted glass with metallic accents, and high-end laminates with realistic wood grains are ideal.

Hospital/Healthcare Facility: Hygiene and cleanability are non-negotiable. Solid surface (seamless), stainless steel, and certain laminates with antimicrobial properties are the best options.

Retail/Mall: Balance durability with visual appeal. Decorative laminates in bold patterns or colors, and scratch-resistant elevator panels like stainless steel, can withstand high traffic while making a brand statement.

Residential Home Elevator: Reflect the home’s interior design. For a traditional home, wood panels are perfect. For a modern home, consider stainless steel, glass, or a custom laminate.

Industrial/Service Elevator: Function over form. Durable elevator wall solutions like thick-grade stainless steel or functional FRP are designed to withstand impact and abuse.

Beyond the Material: Fabrication and Installation

Choosing the material is only half the battle. The quality of fabrication and installation is critical to achieving the final look and performance.

Fabrication: Look for fabricators who specialize in elevator interiors. Precision cutting, seamless joining (especially for solid surface and laminate), and perfect finishing are what separate a good installation from a great one.

Installation: Professional installers understand the nuances of working within an elevator cab—aligning panels perfectly, ensuring secure attachment to the cab structure, and navigating the cab’s unique geometry.

Investing in Long-Term Value

Your choice of elevator interior wall panels is a long-term investment. While upfront cost is a factor, consider the total cost of ownership. A more durable, easy-to-maintain material like stainless steel or solid surface may have a higher initial price but will save significantly on maintenance, cleaning, and replacement costs over a 15-20 year lifespan. Conversely, a cheaper material that requires frequent repair or replacement is a false economy.

By carefully weighing the factors of traffic, budget, maintenance, and design, you can select the perfect elevator wall panel material that delivers both enduring durability and timeless elegance, ensuring every journey is a positive reflection of your property’s standards.

English

English عربى

عربى Deutsch

Deutsch Español

Español Français

Français русский

русский 日本語

日本語 简体中文

简体中文