Elevators are among the most heavily used mechanical systems in modern buildings. From office towers to residential complexes, they endure daily traffic that places significant stress on both their machinery and interiors. While much attention is often given to the engineering of elevator motors, cables, and safety systems, the interior environment plays an equally critical role in long-term performance. One of the key components that safeguard the cabin is the elevator interior wall panel. These panels do more than provide aesthetic value—they act as protective barriers that extend the life of the elevator itself.

The Function of Elevator Interior Wall Panel

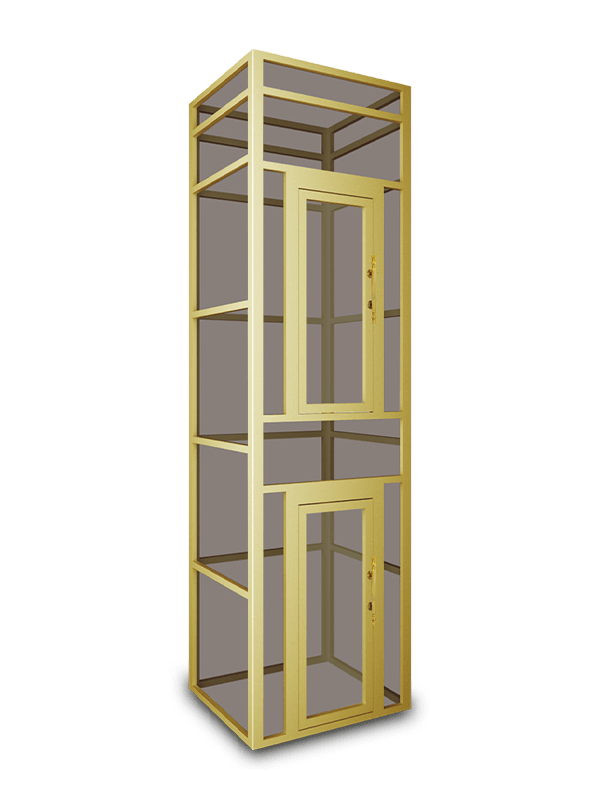

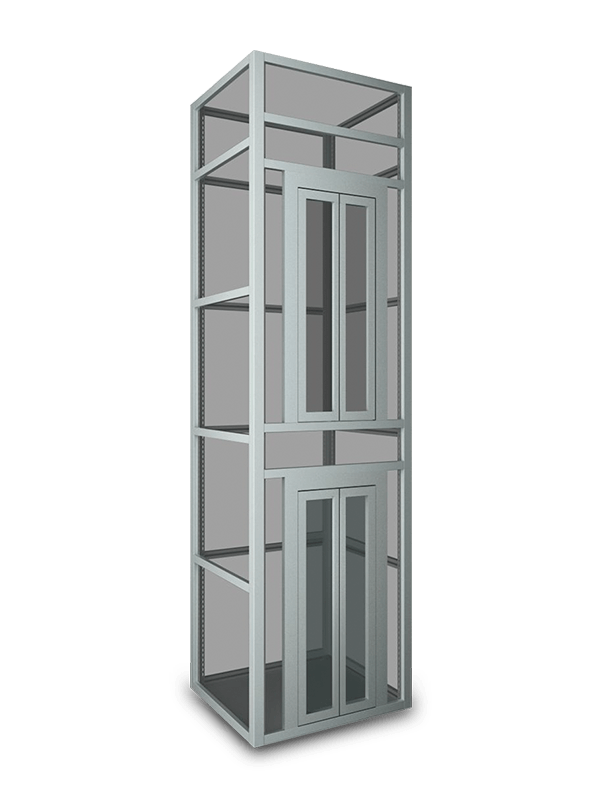

Elevator interior wall panels are the visible surfaces that line the cabin walls. They come in various materials such as stainless steel, laminate, glass, stone, and composite options. While their appearance sets the tone for a passenger’s experience, their functional role is often underestimated.

The primary purpose of wall panels is to shield the elevator’s structural walls from scratches, dents, and other forms of wear. Without this layer of protection, the underlying structure would be directly exposed to impacts, which could compromise both aesthetics and performance.

Protection Against Physical Damage

Elevators serve diverse purposes depending on the building type. In residential towers, panels may encounter light scratches from luggage or shopping carts. In commercial buildings, they face heavy daily use with briefcases, rolling chairs, or maintenance equipment passing through. Hospitals and industrial facilities place even greater stress on elevators, often transporting beds, stretchers, or bulky tools.

Wall panels absorb much of this contact. Instead of permanent damage to the core elevator cabin, scratches and dents occur on the panels, which are easier to repair or replace. Durable panel materials like stainless steel or high-pressure laminate can resist impact, significantly reducing the likelihood of visible damage.

By serving as a sacrificial yet protective layer, wall panels preserve the structural integrity of the elevator enclosure and prevent costly repairs to the cabin itself.

Resistance to Corrosion and Environmental Stress

Beyond physical impacts, elevators can also face environmental stressors. In coastal areas, salt-laden air can accelerate corrosion. In humid climates, moisture can seep into surfaces, causing rust or warping.

Wall panels designed with corrosion-resistant materials provide an additional safeguard. Stainless steel, for example, resists rusting, while treated laminates and composites can withstand moisture exposure. By shielding the elevator’s interior walls from direct contact with environmental factors, panels ensure that the cabin maintains its performance and structural soundness over time.

Contribution to Fire and Safety Standards

Elevator interiors must comply with strict building codes and safety regulations. Wall panels often play a role in meeting these requirements, especially when constructed from fire-rated or non-combustible materials.

While their primary role is not mechanical safety, panels made of fire-resistant laminates, metals, or composites can delay the spread of flames and reduce smoke generation during emergencies. This not only protects passengers but also minimizes damage to the elevator cabin during incidents. Durability in this context goes beyond wear and tear—it encompasses resilience under critical conditions.

Noise Reduction and Passenger Comfort

Durability is not solely about withstanding damage—it also includes maintaining performance and comfort over years of operation. Noise is a common issue in elevators, particularly when panels or walls vibrate from movement or contact.

Well-fitted wall panels dampen vibrations and reduce sound transmission inside the cabin. This prevents rattling, maintains a quieter environment, and reduces stress on the elevator structure caused by constant movement. A quieter cabin also enhances passenger experience, making the elevator feel solid and reliable.

Simplifying Maintenance and Cleaning

Maintenance plays a major role in the life span of an elevator. Wall panels designed with smooth, resilient finishes are easier to clean and less prone to staining.

For example, stainless steel panels can be wiped down with standard cleaning solutions, while laminates resist fingerprints and surface marks. By streamlining cleaning routines, these panels reduce the frequency of deep maintenance and keep elevators presentable with minimal effort.

This ease of maintenance not only improves aesthetics but also prevents long-term deterioration. Panels that resist stains and scratches ensure that small issues do not accumulate into larger problems, thereby extending service life.

Replacement Versus Structural Repairs

Another way wall panels enhance durability is by offering a replaceable surface layer. Over time, even the most resilient materials show wear. Panels, however, can be swapped without disrupting the core elevator structure.

This modularity reduces downtime and prevents costly overhauls. Instead of repairing structural walls, building managers can simply replace worn or damaged panels, which restores both the appearance and protective function of the cabin. The result is a more sustainable and economical maintenance strategy.

Role in High-Traffic Environments

The durability benefits of wall panels become especially apparent in high-traffic environments. Consider airports, shopping malls, or hospitals, where thousands of passengers use elevators daily. Without wall panels, the cabin walls would quickly show signs of wear, undermining both safety and appearance.

In these settings, reinforced panels—sometimes with corner guards or bump rails—take the brunt of impacts. This ensures that elevators continue to function safely even under extreme usage conditions, reducing downtime and preventing premature replacement.

Supporting Long-Term Cost Efficiency

Elevators represent a significant investment for building owners. The cost of installation, operation, and maintenance is substantial, which is why protecting this investment is essential.

By preventing damage, wall panels reduce the need for frequent structural repairs. Their resistance to corrosion, fire, and impact lowers the likelihood of major incidents that could compromise safety or performance. In the long run, the cost of installing durable panels is far outweighed by the savings generated through reduced maintenance and extended elevator life span.

The Intersection of Durability and Design

Durability does not have to come at the expense of design. Modern wall panels are engineered to provide both resilience and aesthetic appeal. Whether clad in sleek metals, warm laminates, or sophisticated glass, panels can complement the building’s architectural style while safeguarding the cabin.

This combination of form and function ensures that elevators not only last longer but also contribute positively to the building’s image. A well-maintained, durable elevator interior conveys reliability and attention to detail, which influences tenant and visitor perceptions.

Sustainability Considerations

In recent years, sustainability has become a driving factor in construction and interior design. Elevator wall panels can play a role here as well. Durable panels mean fewer replacements, which reduces material waste. Some panel materials are recyclable or sourced from sustainable processes, further lowering the environmental impact.

By choosing long-lasting materials that align with eco-friendly goals, building owners achieve durability while supporting broader sustainability initiatives.

Future Outlook: Innovations in Wall Panel Technology

As technology advances, elevator wall panels are evolving to offer even greater durability. Some new materials integrate nanotechnology for scratch resistance, while others incorporate antimicrobial surfaces for enhanced hygiene in public spaces.

These innovations not only improve long-term performance but also address modern concerns such as health and sustainability. Elevators of the future may feature wall panels that adapt to environmental conditions, self-heal minor scratches, or integrate smart sensors to monitor wear—all of which further enhance durability.

Conclusion

Elevator interior wall panels are far more than decorative finishes. They are integral components that safeguard the cabin against physical damage, corrosion, and environmental stress. They simplify maintenance, enhance safety, reduce noise, and support cost efficiency. In high-traffic environments, panels act as the first line of defense, ensuring that elevators continue to perform reliably despite constant use.

Durability in elevators is not achieved by machinery alone; it is equally shaped by thoughtful design choices within the cabin. By installing resilient and functional wall panels, building owners extend the life of their elevators, reduce maintenance burdens, and ensure a safe, comfortable experience for passengers.

Ultimately, the contribution of elevator wall panels to durability highlights the importance of considering every detail in elevator design—not just for appearance, but for long-term performance and sustainability.

English

English عربى

عربى Deutsch

Deutsch Español

Español Français

Français русский

русский 日本語

日本語 简体中文

简体中文