The utility model relates to a lifting device for a low-rise building.

Currently, most units and residents live on 37 floors, and most buildings do not have elevators. Therefore, it is inconvenient for the residents upstairs and downstairs. 1, elderly, frail, sick and disabled households when the following are more difficult; 2 are mobile bicycles; 3 are gas tanks, coal, charcoal, firewood and ashes; 4 are carrying, moving and reducing furniture. At present, the elevators produced by elevator factories are expensive, complicated to install, and have high requirements. In addition, the state also stipulates that no buildings shall be installed in buildings with less than six floors. So you don't need to install an elevator.

The purpose of this utility model is to provide a simple lifting device, which can be widely used in low-rise buildings in rural areas and rural areas to solve the problem of old, weak, sick, disabled, going downstairs, riding bicycles up and down buildings, various fuels and various Items are on the ground and downstairs.

The utility model is realized in this way. A 220-volt AC power motor is installed on the top of the building to drive the hoist to collect and place a wire rope of a planetary gear transmission with a small tooth difference. Safety devices that can automatically stop when wire ropes, railings, floors, guides and wire ropes are disconnected, and reach different floors through the buttons of the lifting bucket and the lifting device on each floor.

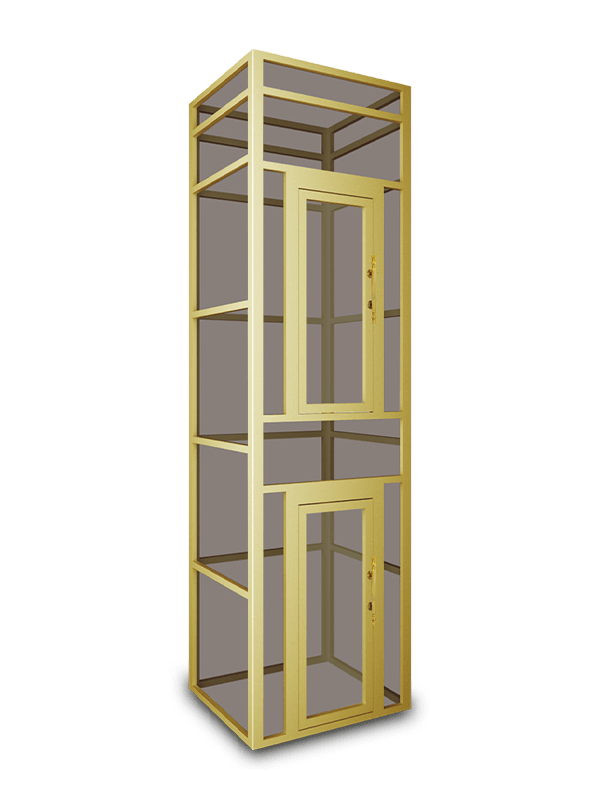

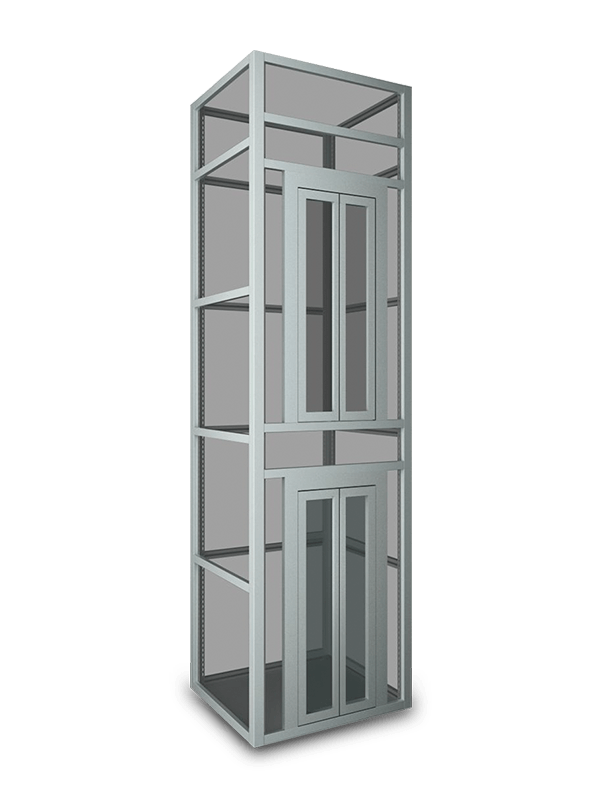

The device consists of a lifting bucket, a lifting device, a guiding mechanism and a control circuit.

First, the roof-panel-mounted lifter is driven by a single-phase electric motor via a pulley driven by a planetary gearbox with low-tooth difference. A reel is installed on the output shaft of the gearbox, and there is a wire rope on the reel to lift the elevator bucket. Due to the high efficiency of use and the self-locking planetary gear gearbox with small tooth difference, the motor power is very small, and the gearbox can be reversed to help lift the bucket by its own weight when it falls. In addition, an electromagnetic brake is also mounted on the motor shaft. When the bucket needs to stop, the electromagnetic brake can be used to brake.

The second is that the guide column is a long column composed of two pipes, and an iron pipe with a gap at the top is this device.

The guiding mechanism composed of the simple elevator guide rail and the guide frame on the lifting bucket can ensure the smooth operation of the lifting bucket. There are also tie rods on both sides of the guide rail, and the rubber rollers are also installed in the guide frame to make the lifting operation more stable and reduce noise. When the wire rope breaks, the guide rail can also work together with the brake hoop on the bucket to make the bucket drop slowly, ensuring absolute safety.

three. The control circuit consists of control buttons, overcurrent protection circuit and power circuit installed on the lifting bucket and each floor. With the help of the control circuit, the elevator can go up and down in each floor or in the hoisting barrel.

Fourth, the lift cabin is the place to carry people. This is a square frame welded from iron garden iron. Doors are opened and closed for the convenience of people and things. The floor is laid at the bottom, there are railings around the walls, and the upper arm is on the bucket lifted by the wire rope through the pulley. Pull the boom to the pull-down spring, and lift the bucket through the lift pin and bucket to prevent sun and rain. The roof is equipped with a glass fiber reinforced plastic roof, the guide frame is welded on the edge, the roller is installed in the middle of the guide frame, and the end of the crane arm is also equipped with a brake hoop. The brake ring is a ring at the end of the boom. The ring is inside the ring. The ring is inside the ring. There is a loop at the end of the crane arm. There is a ring on the inside of the guide arm. The ring is inside the ring. There is a loop at the end of the hanger. A protruding steel plate and brake pads. When the wire rope breaks suddenly, the crane arm is pulled down by the brake spring, and then the brake hoop is inserted into the guide rail, the friction between the brake disc and the guide rail makes the bucket level with the building and leaves the lift bucket.

The technical performance of the utility model is that the power supply is 220 volts and below and below and the DC power supply (380 volts is better), the motor is 1 kilowatt, the lifting bucket weight is 200 kilograms, the weight is 300 kilograms, the lifting speed of 300 kilograms, the 10m/deer drop bucket size is 2000 x 1000 x 1500 mm line R.

English

English عربى

عربى Deutsch

Deutsch Español

Español Français

Français русский

русский 日本語

日本語 简体中文

简体中文