Understanding Villa Elevators and Their Benefits

A villa elevator is a vertical transportation system designed specifically for private residential properties, offering both practical mobility solutions and luxury enhancement. Unlike commercial elevators, these systems are tailored to home environments with capacities typically ranging from 2 to 6 passengers and load limits between 250-450 kg. Modern villa elevators combine sophisticated engineering with aesthetic design, transforming multi-story homes into accessible, future-proof living spaces while potentially increasing property values by 10-15% according to real estate market data.

The primary advantages extend beyond convenience. For aging homeowners, villa elevators eliminate mobility barriers, allowing residents to age in place comfortably. Families with young children benefit from safer vertical movement compared to stairs, while the added functionality appeals to prospective buyers in competitive housing markets. Installation during construction costs significantly less than retrofitting, making early planning essential for budget-conscious homeowners.

Types of Villa Elevators Available

Hydraulic Elevators

Hydraulic systems use fluid-driven pistons to move the cabin and represent the most common choice for 2-4 story villas. These elevators require a machine room at ground level or basement to house the hydraulic pump and controller. The typical travel speed ranges from 0.15 to 0.3 meters per second, suitable for residential use. Installation costs average $25,000-$40,000 depending on customization, with operating expenses around $300-$500 annually for maintenance and electricity.

Traction Elevators

Traction systems utilize steel cables and counterweights, operating with greater energy efficiency than hydraulic alternatives. These elevators can be machine-room-less (MRL), saving valuable space in compact villas. With travel speeds up to 1 meter per second, traction elevators handle taller structures more effectively. The initial investment ranges from $30,000-$50,000, but energy consumption is approximately 40% lower than hydraulic models, resulting in long-term savings of $150-$250 per year.

Pneumatic Vacuum Elevators

These innovative elevators use air pressure differential to move transparent polycarbonate cabins through aluminum tubes. Requiring no pit or machine room, pneumatic elevators install in as little as 2-3 days with minimal structural modifications. The self-supporting design accommodates 1-3 passengers with weight limits of 159-525 pounds. Pricing starts at $35,000 for single-passenger models, with the sleek, modern aesthetic appealing to contemporary villa designs.

| Elevator Type | Cost Range | Speed (m/s) | Space Required | Installation Time |

|---|---|---|---|---|

| Hydraulic | $25,000-$40,000 | 0.15-0.3 | Machine room required | 3-5 weeks |

| Traction (MRL) | $30,000-$50,000 | 0.5-1.0 | Minimal overhead space | 4-6 weeks |

| Pneumatic | $35,000-$55,000 | 0.15 | No pit/machine room | 2-3 days |

Space and Structural Requirements

Proper planning for a villa elevator begins with understanding spatial demands. Standard residential elevator shafts require a minimum footprint of 1.2m × 1.5m, though compact models can fit within 1m × 1m spaces. The shaft must extend from the lowest to highest service level with adequate overhead clearance, typically 3.5-4 meters above the top floor to accommodate machinery and safety buffers.

Structural considerations include:

- Load-bearing capacity of floors to support elevator weight plus maximum passenger load (typically 1,500-2,500 kg total)

- Pit depth ranging from 100mm for some MRL systems to 1,200mm for traditional hydraulic elevators

- Reinforced concrete or steel framework surrounding the shaft for stability and sound insulation

- Electrical supply of 220-380V three-phase power with dedicated circuit breakers

- Emergency communication systems connecting to main phone lines or cellular networks

For retrofitting existing villas, structural engineers must assess whether current foundations can support additional loads. External elevator installations attached to the building exterior offer alternatives when interior space is limited, though these require weather-resistant materials and architectural approval in some jurisdictions.

Installation Process and Timeline

The installation journey follows a structured sequence that homeowners should anticipate when budgeting time and resources. Total project duration typically spans 6-12 weeks from initial consultation to final inspection, though this varies based on elevator type and construction complexity.

Phase One: Planning and Permits

The first 2-3 weeks involve site assessment, architectural integration, and regulatory approvals. Professional elevator consultants measure available space, evaluate electrical capacity, and create detailed installation plans. Building permits required by most municipalities cover structural modifications, electrical work, and elevator-specific safety compliance. In jurisdictions with strict codes, this phase may extend to 4-6 weeks.

Phase Two: Construction Preparation

Weeks 3-5 focus on creating the shaft infrastructure. Contractors excavate pits if necessary, pour concrete foundations, construct shaft walls, and install guide rails. This phase generates significant noise and dust, requiring temporary relocation of residents in some cases. Electrical contractors simultaneously run dedicated power lines and install control panels.

Phase Three: Elevator Installation

During weeks 6-8, technicians install the elevator car, motor systems, cables or hydraulic components, and control mechanisms. Each component undergoes calibration to ensure smooth operation. Door mechanisms receive particular attention, as they represent the most frequently serviced elevator parts. Modern installations incorporate programmable logic controllers (PLCs) that allow customization of speed profiles, door timing, and floor prioritization.

Phase Four: Testing and Certification

The final 1-2 weeks involve comprehensive safety testing. Certified inspectors verify emergency braking systems, backup power functionality, weight capacity limits, and compliance with residential elevator codes such as ASME A17.1 in North America or EN 81-41 in Europe. Only after passing all inspections can the elevator receive operational certification and homeowner training on proper use and emergency procedures.

Cost Breakdown and Financial Considerations

Understanding the complete financial picture enables informed decision-making beyond the initial purchase price. Total ownership costs over 20 years typically reach 1.5-2 times the installation expense when factoring maintenance, repairs, and energy consumption.

Initial Investment Components

The base elevator unit accounts for 50-60% of initial costs, while installation labor represents 25-30%. Remaining expenses include shaft construction (10-15%), electrical work (5-8%), and permits/inspections (2-5%). Premium finishes such as hardwood paneling, custom lighting, or glass walls add $5,000-$15,000 to base prices. Smart home integration with touchscreen controls and smartphone connectivity increases costs by $2,000-$4,000 but enhances user experience and property appeal.

Operating and Maintenance Expenses

Annual maintenance contracts typically cost $300-$800, covering biannual inspections, lubrication, and minor adjustments. These agreements often include emergency service within 24 hours. Major component replacements arise every 10-15 years, with costs including:

- Door operators: $1,500-$3,000

- Control systems: $3,000-$6,000

- Cables (traction systems): $800-$1,500

- Hydraulic pumps: $4,000-$7,000

Energy consumption varies by type, with hydraulic elevators using approximately 3-5 kWh per day ($100-$180 annually) while efficient traction systems consume 1.5-3 kWh daily ($50-$110 annually). Installing LED cabin lighting and standby mode features reduces consumption by an additional 15-20%.

Financing Options

Many homeowners incorporate elevator costs into construction loans or refinance existing mortgages to capture current low interest rates. Home equity lines of credit (HELOCs) provide flexible funding, while some elevator companies offer installment plans at 0-6% APR for qualified buyers. In regions with aging-in-place initiatives, government grants or tax credits may offset 10-30% of installation costs for accessibility improvements.

Safety Features and Compliance Standards

Modern villa elevators incorporate multiple redundant safety systems that exceed commercial building requirements in many aspects. All residential elevators must include emergency braking mechanisms that engage automatically if descent speed exceeds safe parameters, typically activating within 0.3 seconds of detection. These brakes use spring-loaded or gravity-activated designs that function even during complete power loss.

Essential safety components include:

- Overspeed governors that monitor car velocity and trigger brakes if safe limits are exceeded

- Door interlocks preventing car movement unless all doors are fully closed and latched

- Battery backup systems providing power for controlled descent to the nearest floor during outages

- Emergency communication via telephone or intercoms connecting to external monitoring services

- Backup lighting activating automatically if main power fails, illuminating the cabin for safe exit

- Weight sensors preventing operation when maximum capacity is exceeded, with audible warnings

Regulatory compliance varies globally but generally follows ASME A17.1 standards in North America, which mandate annual inspections by certified technicians. European installations adhere to EN 81-41 specifications designed specifically for private residential use. These codes address everything from minimum cabin dimensions (ensuring wheelchair accessibility) to emergency evacuation procedures. Homeowners should verify that installers maintain proper licensing and that equipment carries certification marks from recognized testing laboratories such as UL, CE, or equivalent authorities.

Child safety deserves special attention in family homes. Key-operated controls prevent unsupervised use by young children, while infrared sensors detect obstructions in doorways, reversing closure immediately upon contact detection. Some advanced models include weight distribution sensors that alert users to unstable loading conditions before movement begins.

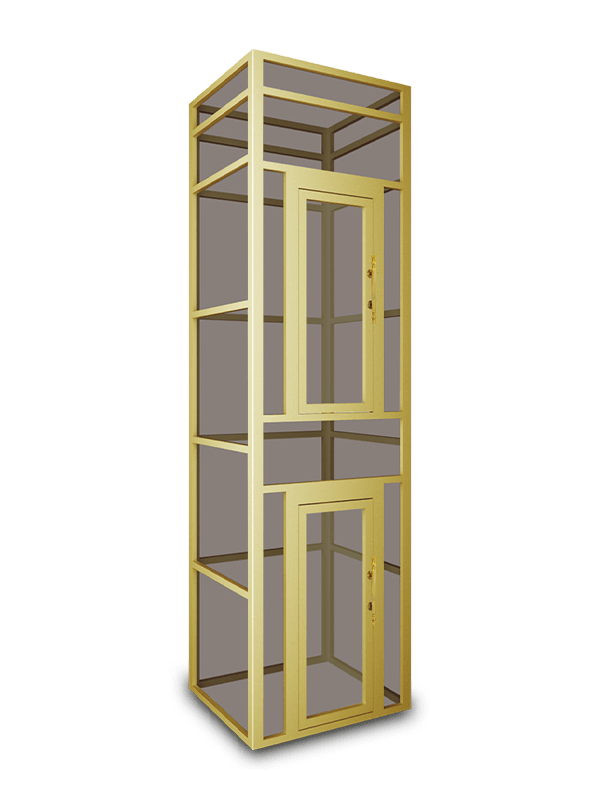

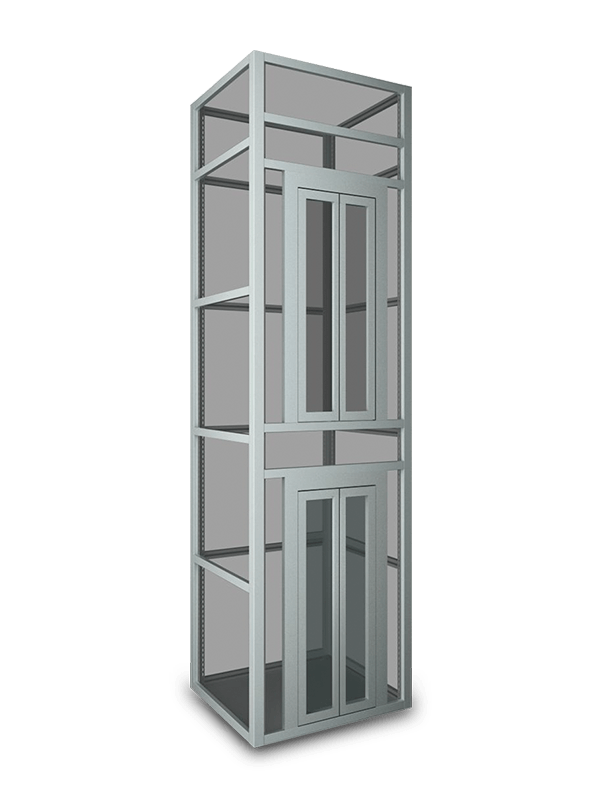

Customization and Design Integration

Villa elevators offer extensive personalization to complement interior design themes. Cabin finishes range from polished stainless steel and mirrored glass to exotic wood veneers and custom digital prints, allowing seamless integration with surrounding décor. High-end manufacturers provide nearly unlimited material options, with popular choices including Italian marble inlays, leather-wrapped handrails, and artisan-crafted metalwork.

Architectural Considerations

Transparent or semi-transparent elevator designs create visual drama while maximizing natural light flow. Panoramic glass cabins suit modern villas with open floor plans and scenic views, though they require higher-grade tempered or laminated glass panels that increase costs by $8,000-$15,000. For traditional estates, ornate wrought iron gates and classic wood paneling maintain period authenticity while providing modern convenience.

Door configurations adapt to spatial constraints and aesthetic preferences. Center-opening doors maximize cabin width for wheelchair access, while side-opening designs suit narrower hallways. Automatic versus manual operation affects both convenience and cost, with powered doors adding $2,500-$4,000 but eliminating physical strain for elderly or disabled users.

Technology Integration

Smart home connectivity transforms basic elevators into integrated household systems. Available features include voice-activated controls compatible with Amazon Alexa or Google Assistant, destination dispatch algorithms that predict floor requests based on usage patterns, and smartphone apps enabling remote summoning before arriving home. Advanced models incorporate air purification systems, ambient lighting that adjusts to time of day, and built-in speakers for music streaming during transit.

Touchscreen interfaces replace traditional button panels in luxury installations, offering customizable display themes and multilingual options. Some systems integrate with home security networks, requiring PIN codes or biometric authentication before operation—particularly valuable in villas with staff access or teenage drivers who might otherwise misuse elevator privileges.

Maintenance Best Practices and Longevity

Proactive maintenance extends elevator lifespan to 20-30 years while minimizing unexpected breakdowns. Manufacturers recommend professional inspections every six months, during which technicians lubricate moving parts, test safety systems, inspect cables or hydraulic seals for wear, and recalibrate sensors. Between professional visits, homeowners should monitor for unusual sounds such as grinding, squealing, or bumping, which often indicate developing issues requiring immediate attention.

Common maintenance tasks include:

- Cleaning door tracks monthly to prevent debris accumulation that causes jamming

- Testing emergency communication systems quarterly to ensure functionality during power outages

- Replacing cabin lighting as needed, upgrading to LED for longer intervals between changes

- Maintaining clear ventilation to prevent heat buildup in machine rooms or overhead spaces

- Keeping detailed service logs documenting all inspections, repairs, and part replacements

Hydraulic systems require particular attention to fluid levels and seal integrity. Annual hydraulic oil analysis detects contamination before it damages pumps or cylinders, preventing costly repairs averaging $5,000-$10,000. Traction elevators need cable inspection for fraying or corrosion, with replacement recommended when wear indicators show 10% reduction in cable diameter.

Warranty coverage typically spans 1-2 years for standard components, with extended warranties available for 5-10 years at 10-15% of initial equipment cost. These policies prove worthwhile for complex electronic systems where controller failures can cost $4,000-$8,000 to repair. When selecting service providers, prioritize companies with factory-certified technicians who maintain access to original manufacturer parts, ensuring compatibility and optimal performance throughout the elevator's service life.

Impact on Property Value and Market Appeal

Real estate professionals consistently report that villa elevators enhance marketability and sale prices. Properties equipped with elevators sell 15-25% faster than comparable homes without vertical transportation, according to data from luxury real estate markets in California, Florida, and New York. The value addition varies by regional demographics—markets with aging populations show higher premiums, while areas with younger buyers may see modest increases unless the home exceeds three stories.

Appraisers typically assign added value equivalent to 50-75% of installation costs for newer systems in good condition. A $40,000 elevator installation might therefore increase appraised value by $20,000-$30,000. This calculation considers the elevator's remaining useful life, maintenance history, and market demand for accessibility features. Homes marketed as "aging-in-place ready" or "multi-generational living spaces" command particular premiums in retirement-destination markets.

Beyond direct financial returns, elevators expand the potential buyer pool to include individuals with mobility limitations, multi-generational families, and luxury-seekers who view home elevators as essential amenities rather than optional upgrades. This broader appeal reduces time-on-market and strengthens negotiating positions for sellers. However, poorly maintained or outdated elevator systems can become liabilities, with potential buyers requesting $15,000-$25,000 price reductions to cover modernization costs or removal expenses if the system proves irreparable.

English

English عربى

عربى Deutsch

Deutsch Español

Español Français

Français русский

русский 日本語

日本語 简体中文

简体中文