Elevators are among the most heavily used spaces in modern buildings. From commercial towers to residential complexes, they are subjected to constant traffic day and night. With this frequency of use, the interior surfaces of elevators are prone to wear and tear much faster than many other areas in a building. Scratches, scuffs, stains, and impacts can make an elevator appear worn out, even if its mechanical components are functioning well. This is where elevator background boards play an essential role. By acting as protective panels for the interior walls, they not only add to the aesthetic appeal of the elevator but also significantly improve its durability.

The Demands on Elevator Interiors

Elevators experience high levels of daily traffic. In office towers, residents and visitors enter and exit hundreds of times a day. In retail centers, they are frequently used to move both people and goods. In residential buildings, they are central to daily routines. This continuous activity exposes elevator interiors to constant contact from people, bags, strollers, carts, and sometimes even equipment.

Without protective measures, elevator walls quickly develop dents, scratches, and stains. Over time, these visible signs of damage reduce the overall appeal of the building. Property managers are then faced with the cost and inconvenience of frequent refurbishments. Background boards address this issue by providing a durable surface layer that shields the elevator’s structural walls from direct impact and wear.

Protection Against Physical Damage

One of the primary functions of background boards is to absorb and resist physical damage. Whether an elevator is transporting office workers with laptops or maintenance teams with tools, its walls are constantly at risk. Background boards, designed from durable materials, prevent these items from leaving lasting marks.

For example, stainless steel boards resist scratches and dents better than painted surfaces. Laminated or composite boards provide added resilience by combining strength with shock absorption. In this way, the background boards take the brunt of the physical stress, preserving the underlying elevator structure. This protective quality extends the lifespan of the interior and reduces the need for costly repairs.

Resistance to Stains and Cleaning Chemicals

Another challenge for elevator interiors is exposure to dirt, moisture, and cleaning products. Elevators are enclosed spaces that must remain hygienic, so they require frequent cleaning. If the walls are made from materials that stain easily or react poorly to cleaning agents, they will quickly deteriorate.

High quality background boards are designed with surfaces that resist stains and hold up under regular cleaning. Materials such as stainless steel, laminates, or treated composites can withstand the effects of cleaning solutions without losing their finish. This property ensures that elevators retain a fresh appearance for longer periods, even under intensive cleaning schedules. By resisting stains and chemical wear, background boards contribute significantly to the durability of the interior.

Reducing Maintenance Frequency

Durability in elevator interiors is closely linked to maintenance cycles. The more resistant a surface is to damage, the less frequently it requires repair or replacement. Elevator background boards extend maintenance intervals by acting as a first line of defense.

Instead of repainting or repairing scratched walls every few months, building managers can rely on background boards to maintain a consistent appearance for years. This not only saves costs but also reduces downtime, which is particularly important in buildings where elevators are essential for daily activity. In this way, background boards help create a more sustainable maintenance strategy.

Material Choices and Their Benefits

The durability of background boards is directly influenced by the materials used. Different materials offer unique advantages depending on the building’s needs.

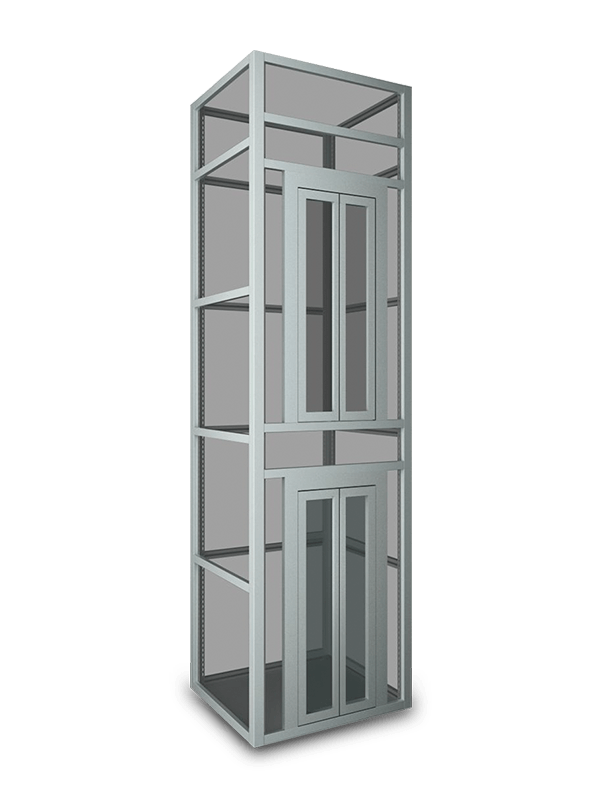

Stainless Steel

Stainless steel is a popular choice for elevator background boards because of its toughness, resistance to corrosion, and long lifespan. It handles impacts well and resists rust even in humid environments. Its surface is easy to clean, making it suitable for hospitals, offices, and residential complexes.

Laminates

Laminated boards combine decorative appeal with durability. They are available in a variety of colors and patterns, allowing for customization without sacrificing strength. Laminates resist scratches and stains, and their layered construction adds structural resilience.

Composite Panels

Composite materials blend natural and synthetic components to achieve a balance between strength and design flexibility. They can be made lightweight while still offering significant resistance to impacts. Their adaptability makes them a versatile choice for modern elevator interiors.

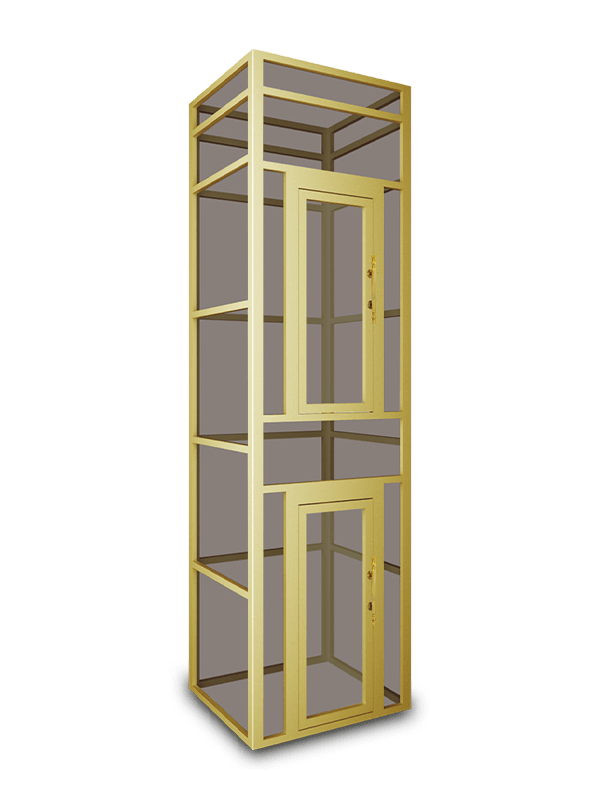

Glass and Mirror Finishes

While more fragile than other options, tempered glass and mirrored boards are designed to be both durable and stylish. Advances in treatment processes make them stronger than standard glass, though they are best suited for elevators where aesthetics are prioritized alongside durability.

By selecting the right material, designers and property managers can tailor the durability of the elevator interior to the specific demands of the building.

Enhancing Safety Alongside Durability

Durability is not only about extending the life of elevator interiors but also about maintaining safety. Damaged or deteriorating walls can pose risks. For example, peeling finishes or sharp edges from cracked surfaces may lead to injuries. Background boards prevent this by providing intact, stable surfaces that remain safe for passengers even after years of use.

Some materials also offer fire-resistant properties, further enhancing safety. By meeting safety standards while resisting damage, background boards ensure that elevator interiors remain both functional and secure.

Preserving Aesthetic Quality

An elevator’s interior is often one of the first spaces people encounter when entering a building. Its appearance contributes to the perception of the property’s quality. If the walls appear scratched, stained, or outdated, it can leave a negative impression. Durable background boards preserve a polished appearance for longer periods, delaying the need for refurbishments.

By maintaining both durability and aesthetics, background boards ensure that elevators contribute positively to the building’s overall image. This dual role makes them an essential element of long term property management.

Cost Efficiency Through Longevity

While the initial installation of durable background boards requires investment, their long term benefits outweigh the costs. By protecting elevator walls, reducing maintenance frequency, and preserving aesthetic appeal, they lower the total cost of ownership.

Frequent refurbishments, repainting, or replacements can quickly add up. By contrast, strong background boards maintain their integrity over many years, providing consistent performance. This cost efficiency is a key factor in their widespread adoption.

Adaptability for Different Building Types

Not all buildings place the same demands on elevator interiors. Commercial towers may require sleek, professional finishes, while residential buildings may prioritize warmth and comfort. Hospitals and schools need surfaces that are hygienic and easy to sanitize. In each of these settings, background boards can be tailored to meet the specific durability requirements.

For example, stainless steel may be favored in high traffic commercial areas, while laminates may suit residential buildings that seek a softer aesthetic. This adaptability allows background boards to enhance durability across a wide range of contexts.

Supporting Sustainability

Durability also has an environmental dimension. Materials that last longer reduce the frequency of replacements, which in turn lowers material waste and resource consumption. By extending the life of elevator interiors, background boards contribute to more sustainable building practices.

Some background boards are also made with eco friendly materials or recyclable components, further supporting sustainability goals. This dual focus on durability and environmental responsibility aligns with the growing emphasis on green building design.

Conclusion

Elevator background boards are more than decorative elements. They play a crucial role in improving the durability of elevator interiors by resisting physical damage, withstanding cleaning processes, reducing maintenance needs, and supporting safety. Through careful material selection, they provide both resilience and design flexibility, making them suitable for a wide range of building types.

Their contribution extends beyond protection. By preserving aesthetic quality, reducing costs, and supporting sustainability, background boards ensure that elevators remain functional, safe, and visually appealing for years. In a building environment where elevators are among the most heavily used spaces, these protective panels are essential for maintaining long term value.

In summary, elevator background boards are an investment in durability. They safeguard interiors from the wear and tear of daily use while enhancing safety, appearance, and cost efficiency. For property owners and designers seeking lasting solutions, they represent a practical and effective way to ensure that elevator interiors stand the test of time.

English

English عربى

عربى Deutsch

Deutsch Español

Español Français

Français русский

русский 日本語

日本語 简体中文

简体中文