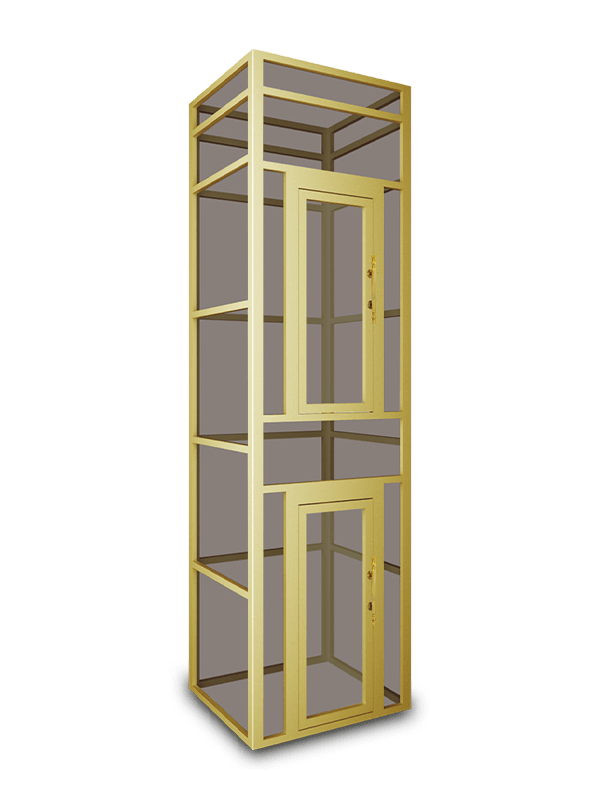

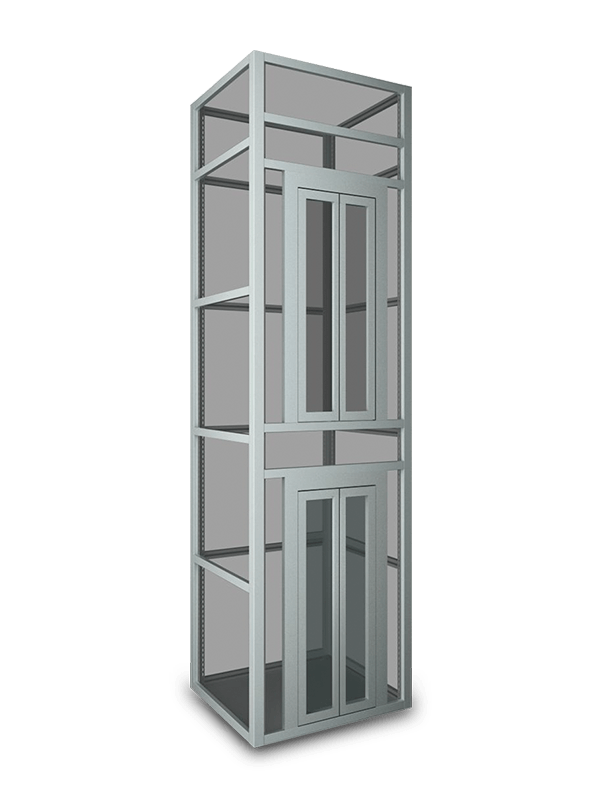

The Elevator Frame Hoistway is a simple and convenient device for moving the cab in an elevator. Its low cost, easy installation, and smooth operation make it an excellent choice for a variety of applications. The elevator frame hoistway is also visually appealing and has a long service life.

Elevator frame hoistways typically have supports that are built into the walls of the building from the lowest floor to the highest. These supports will be specified by the elevator manufacturer. In addition, the elevator contractor should prewire the walls for door interlocks and landing controls. The installation team should also install automatic lighting in the landing areas.

To ensure that the doors are strong enough for the job, elevator frame hoistway doors must meet CSA B44 and ASME A17.1 Safety Code requirements. The door panels must be able to withstand a force of at least 250 lbf (1,112 N) applied on the center of the hoistway door panel. In 1993, the requirement was increased to 1,125 lbf (5,000 N) per panel.

The elevator frame hoistway has an interlock system that stops the descending cars by closing the door. This ensures that the driving machine cannot operate when the door is unlocked. The locking system also prevents the landing door from opening when the car has stopped. The door is secured by a compensating chain made of welded-link steel. When the door is unlocked, the machine cannot operate properly and may cause an accident.

The Elevator Frame Hoistway system includes two mounting members: an upper mounting member and a lower mounting member. The two mounting members are connected by a connection track, which has an adjustment slot that enables postwise adjustment. Hence, alignment of the elevator machine and elevator car is accomplished.

ALUMINUM DERRICK FEATURES

Independent frame glass design, no additional construction cost, good light transmission, and integration with interior decoration;

The installation position is optional, corrosion-resistant and has a long life cycle; industrial-grade aluminum alloy is used, and safety laminated glass is used.

English

English عربى

عربى Deutsch

Deutsch Español

Español Français

Français русский

русский 日本語

日本語 简体中文

简体中文