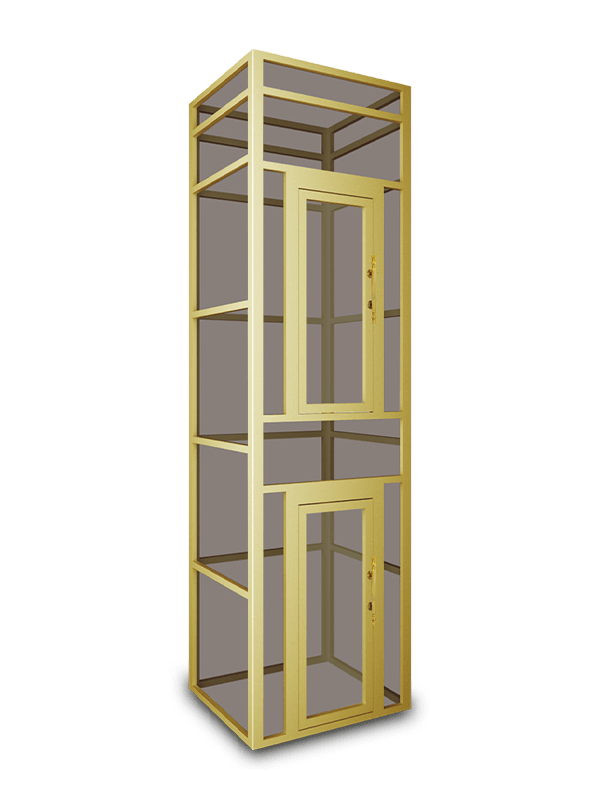

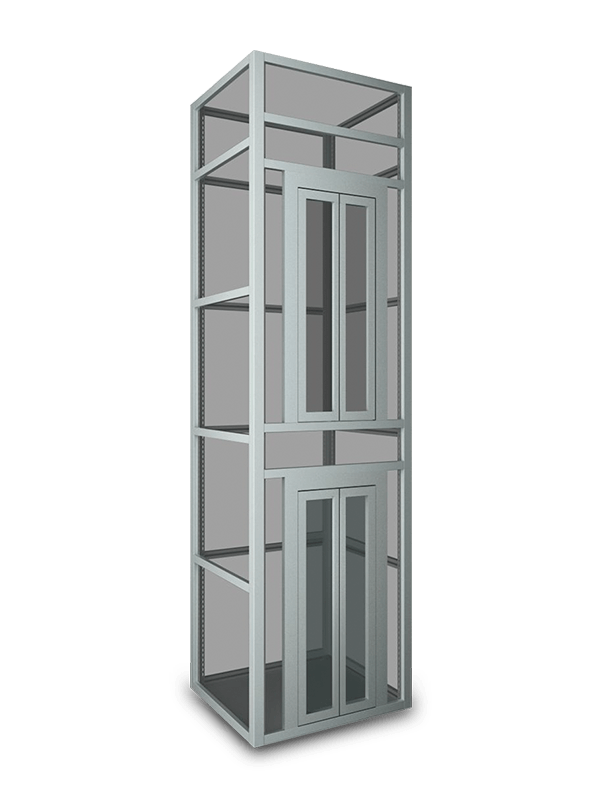

Elevator cabin background boards are a critical yet often overlooked component of elevator interiors. They enhance aesthetics, improve durability, and contribute to passenger safety. This guide covers everything from material selection to installation, helping you make informed decisions.

What is an Elevator Cabin Background Board?

The background board is the interior paneling installed on the walls of an elevator cabin. It serves both functional and decorative purposes, protecting the cabin structure while offering a visually appealing surface.

Popular Materials for Elevator Background Boards

Below are the most common materials used, along with their pros and cons:

| Material | Pros | Cons | Best For |

| Stainless Steel | Durable, fire-resistant, modern look | Expensive, shows fingerprints | Commercial buildings, hospitals |

| Laminated Plywood | Cost-effective, customizable designs | Less durable, prone to water damage | Residential elevators, low-traffic areas |

| Tempered Glass | Sleek appearance, easy to clean | Fragile, high maintenance | Luxury buildings, offices |

| Acrylic/PVC | Lightweight, affordable, variety of colors | Scratches easily, less premium feel | Budget projects, temporary installations |

Key Considerations When Choosing a Background Board

Selecting the right material depends on several factors:

1. Durability and Maintenance

High-traffic elevators (e.g., in malls or offices) need scratch-resistant materials like stainless steel. Residential elevators can opt for laminated wood for a warmer feel.

2. Aesthetic Appeal

Match the board with the building’s interior design. Frosted glass suits modern spaces, while wood grains add a classic touch.

3. Safety and Compliance

Ensure the material meets fire safety codes (e.g., Class A fire rating) and ADA accessibility guidelines if applicable.

Installation Process

Proper installation ensures longevity and performance. Follow these steps:

| Step | Description |

| 1. Measure the Cabin | Accurately measure the interior walls to avoid gaps. |

| 2. Prepare the Surface | Clean and level the substrate to ensure adhesion. |

| 3. Cut the Board | Use appropriate tools (e.g., CNC for precision). |

| 4. Secure the Panel | Use adhesives or mechanical fasteners as needed. |

| 5. Finishing Touches | Seal edges and inspect for alignment. |

Maintenance Tips

Extend the lifespan of your elevator background board with these practices:

- Daily Cleaning: Use a microfiber cloth for stainless steel or glass.

- Avoid Harsh Chemicals: Ammonia can damage acrylic surfaces.

- Inspect for Damage: Replace cracked panels promptly to prevent safety hazards.

Cost Comparison

Below is an approximate cost range per square foot (material only):

| Material | Cost Range (per sq. ft.) |

| Stainless Steel | $20 – $50 |

| Laminated Plywood | $5 – $15 |

| Tempered Glass | $30 – $70 |

| Acrylic/PVC | $10 – $25 |

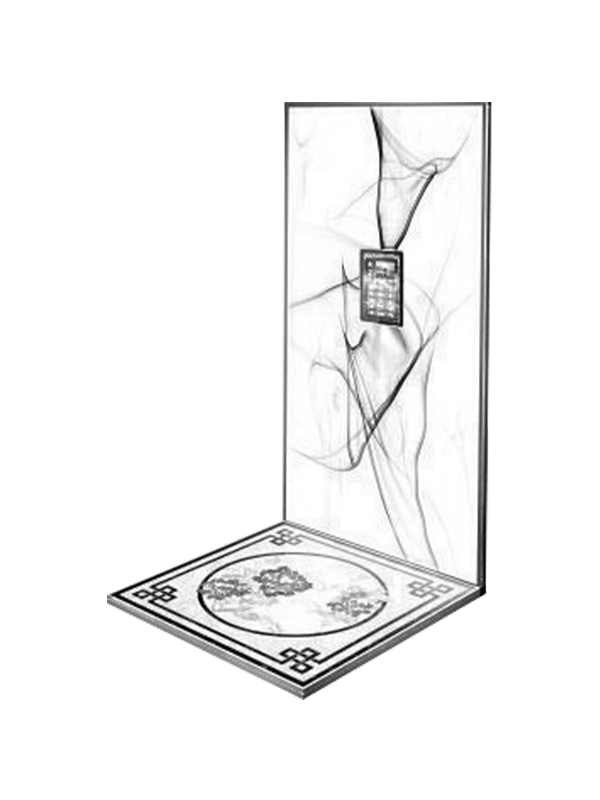

Trends in Elevator Background Board Designs

Current trends include:

- Minimalist Patterns: Subtle textures over bold colors.

- Eco-Friendly Materials: Recycled wood or bamboo.

- Backlit Panels: LED-integrated boards for a futuristic look.

Conclusion

Choosing the right elevator cabin background board involves balancing aesthetics, functionality, and budget. Whether you prioritize durability (stainless steel) or affordability (PVC), this guide helps you navigate the options effectively.

FAQs

Q: Can I install the background board myself?

A: Only if you have experience with carpentry or metalwork. Professional installation is recommended for safety.

Q: How often should the board be replaced?

A: Depends on material—stainless steel lasts 15+ years, while laminated wood may need replacement in 5–8 years.

English

English عربى

عربى Deutsch

Deutsch Español

Español Français

Français русский

русский 日本語

日本語 简体中文

简体中文