Elevator frame hoistway manufacturers must comply with the following standards. The hoistway shall contain a counterweight and main guide rails. The counterweights and guide rails shall be made of steel. They shall be eight-by-nine-inch construction, and must have smooth, parallel surfaces. The counterweights must be securely fastened to the hoistway framing. They shall be equipped with tongue-and-groove or cellular polyurethane elastomer buffers.

Elevator frame hoistway manufacturers must have complete wiring systems connecting all equipment parts. The wiring must be flame and moisture-resistant, and it must be run in metal wire-ways. The traveling cables between the hoistway and the car should be flexible and suspended suitably. They must have an emergency stop switch on the pit. If there is a power failure, the switch should cut off power supply to the motor and the control valves. Additionally, the inspection car must have constant pressure buttons and an incandescent light.

China Custom Elevator Frame Hoistway pits must be equipped with electrical lights and convenience outlets. A light switch must be available in the lower landing. Its power source must be 110 volts. The electrician should be able to connect the light terminals to the elevator pit. The electrical wiring for the pit should comply with local codes.

Elevator car frame shall be equipped with roller guide shoes to prevent excessive lateral movement. In addition, the governor shall activate the elevator car safeties. The safeties should exert equal stopping force on both sides of the guide rail. The operating linkage shall be adjustable. The linkage is connected to the elevator pit via a linkage in the bottom structure of the elevator.

Elevator car doors should be quiet and smoothly operated by an electric operator. They must also be equipped with sill-mounted auxiliary doors. Additionally, the doors should have positive electro-mechanical interlock. Finally, the doors should be zone-locked and automatic two-way leveling must be available.

Elevator wire rope has special provisions. They must be properly configured according to the traction size and the rated load. There should also be sufficient wire rope to ensure safety. Moreover, the brakes are equipped with emergency mechanisms to avoid power failure.

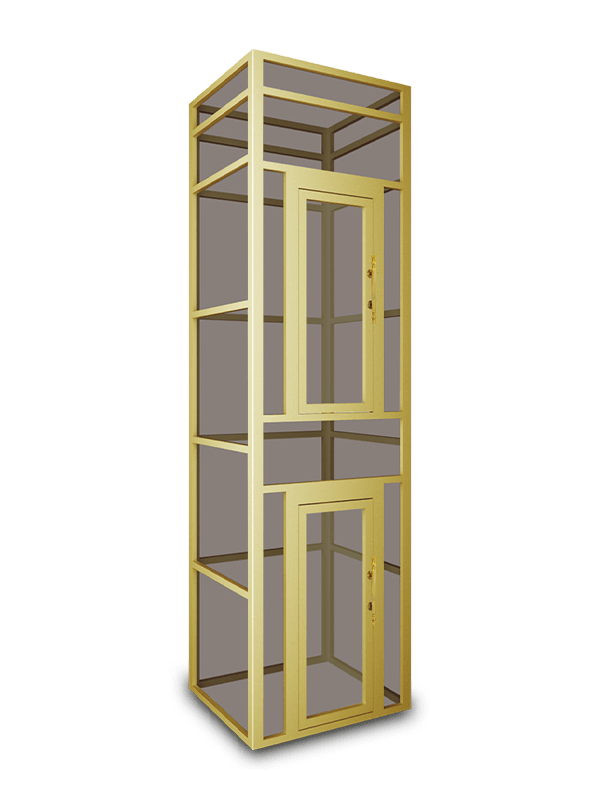

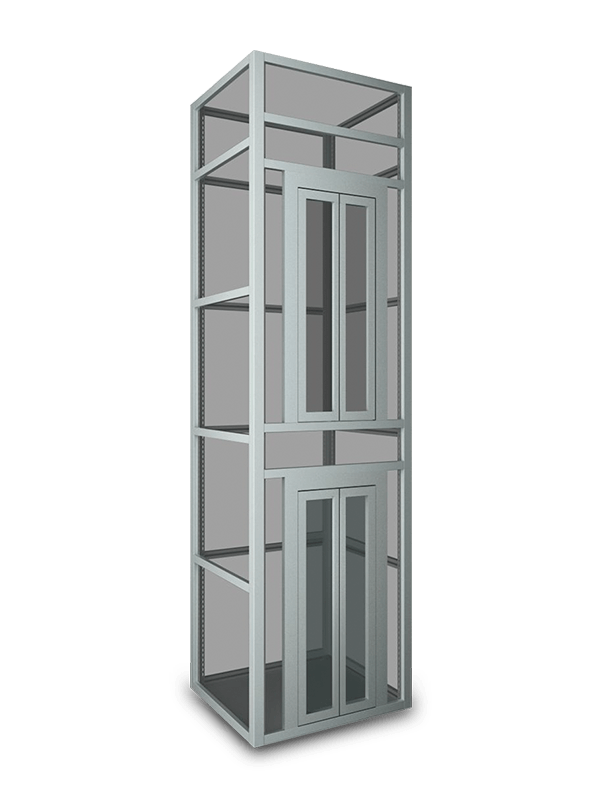

The R&D team can provide customized services for different molds to meet the diverse needs of customers.

1) High-quality production process design and program control, make each batch of custom Blue Elevator Interior Wall Panel more stable and traceable, and obtain high-efficiency production control; strictly follow the supplier's indicators to inspect and monitor the quality of each batch of custom Blue Elevator Interior Wall Panel.

2) The company's superior geographical location and capable management team reduce transportation and labor costs; the professional R&D team and technical service team can continue to provide new products with higher cost performance.

English

English عربى

عربى Deutsch

Deutsch Español

Español Français

Français русский

русский 日本語

日本語 简体中文

简体中文